3D Printed Models

In the dynamic landscape of modern design, a revolutionary technology has emerged, pushing the boundaries of creativity and innovation—the 3D printer. 3D printing has transformed the way we conceptualize and create physical objects, and one particularly captivating application is the production of 3D printed models. In Vadodara, the rise of 3D printing services has further accelerated this change In this blog, we delve into the world of 3D printed models, exploring their versatility, impact on various industries, and the unprecedented possibilities they bring to the realm of design.

In the grand tapestry of technological advancements, 3D scanner for 3D printing in Rajkot stands as a testament to the transformative power of innovation. As this technology continues to evolve, the applications and possibilities for 3D printed models are boundless. From revolutionizing industries to empowering creative expression, the journey from digital design to physical reality through 3D scanning for 3D printing in India is reshaping the way we approach design, production, and problem-solving. The future, it seems, is being built layer by layer, with each printed model marking a step closer to a world of limitless possibilities.

The Versatility of 3D Printed Models

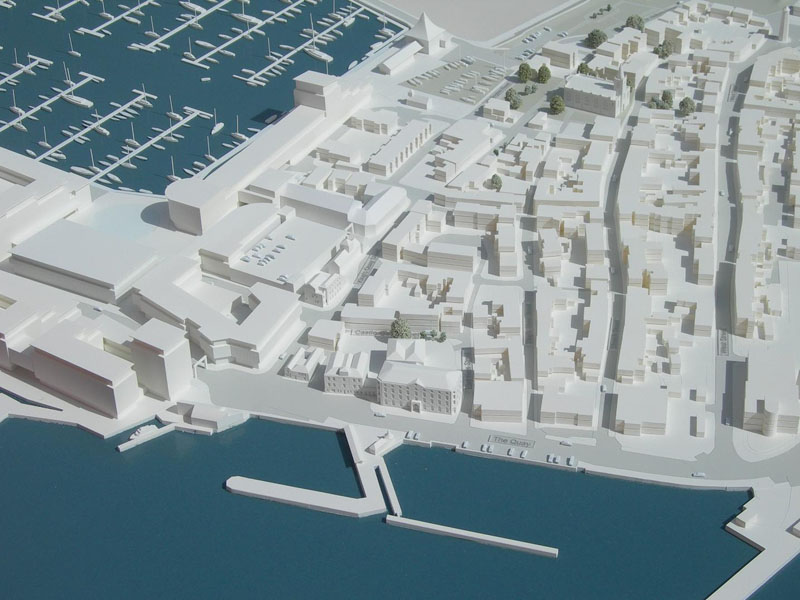

Architectural Precision

3D printed models have become invaluable tools in the field of architecture. Architects and designers can translate intricate digital designs into physical scale models with unparalleled precision. This not only enhances the visualization of complex structures but also allows for rapid prototyping and design iteration.

Engineering Prototypes

In the realm of engineering, 3D printed models serve as functional prototypes for testing and validation. From intricate mechanical components to aerospace parts, engineers can produce accurate prototypes quickly, reducing development time and costs.

Medical Applications

The medical field has embraced 3D printing for the creation of anatomical models, surgical guides, and patient-specific implants. Surgeons can use 3D printed models to plan and practice complex procedures, leading to improved outcomes and personalized healthcare solutions.

Educational Tools

3D printed models have become invaluable assets in educational settings. From biology classes with detailed anatomical models to history lessons with historical artifacts, these tactile representations enhance the learning experience by providing a hands-on, interactive approach.

The 3D Printing Process: From Digital to Physical

Digital Design

The journey of a 3D printed model begins with digital design. Using computer-aided design (CAD) software, designers create a detailed 3D model of the object. This digital file serves as the blueprint for the 3D Printing Services.

Slicing and Layering

The digital model is then sliced into layers using specialized software. This layer-by-layer approach is fundamental to the 3D Printing Services. Each layer is precisely printed on top of the previous one, gradually building the physical object.

Printing Materials

A wide range of materials can be used in 3D printing, including plastics, metals, ceramics, and even bio-compatible materials. The choice of material depends on the desired properties of the final object, such as strength, flexibility, or heat resistance.

Post-Processing

Once the printing is complete, post-processing may be required. This can involve removing support structures, smoothing surfaces, or applying finishes to achieve the desired appearance. Post-processing plays a crucial role in refining the final quality of the 3D printed model.

The Impact on Industries and Future Possibilities

Reduced Time and Cost

3D printing accelerates the prototyping and manufacturing process, significantly reducing both time and costs. This efficiency is particularly beneficial in industries where rapid iteration and customization are essential.

Innovations in Customization

The ability to create highly customized objects is a hallmark of 3D printing. From personalized consumer products to tailor-made medical implants, this technology empowers designers to cater to individual needs with unprecedented precision.

Sustainability and Waste Reduction

3D printing allows for more efficient use of materials, minimizing waste in the manufacturing process. Additionally, the on-demand nature of 3D printing reduces the need for large-scale production and storage, contributing to a more sustainable approach to manufacturing. For 3D printers and scanners services in Gujarat, this technology offers innovative solutions tailored to local industrial needs.

Space Exploration and Beyond

The versatility of 3D printing extends to space exploration, where it is utilized to manufacture tools and parts on demand. This capability opens up new possibilities for sustained human presence in space by reducing the need to transport every required item from Earth.