3D Scanning of Industrial Plant

- Home

- 3D Laser Scanning

- 3D Scanning of Industrial Plant

3D Laser Scanning

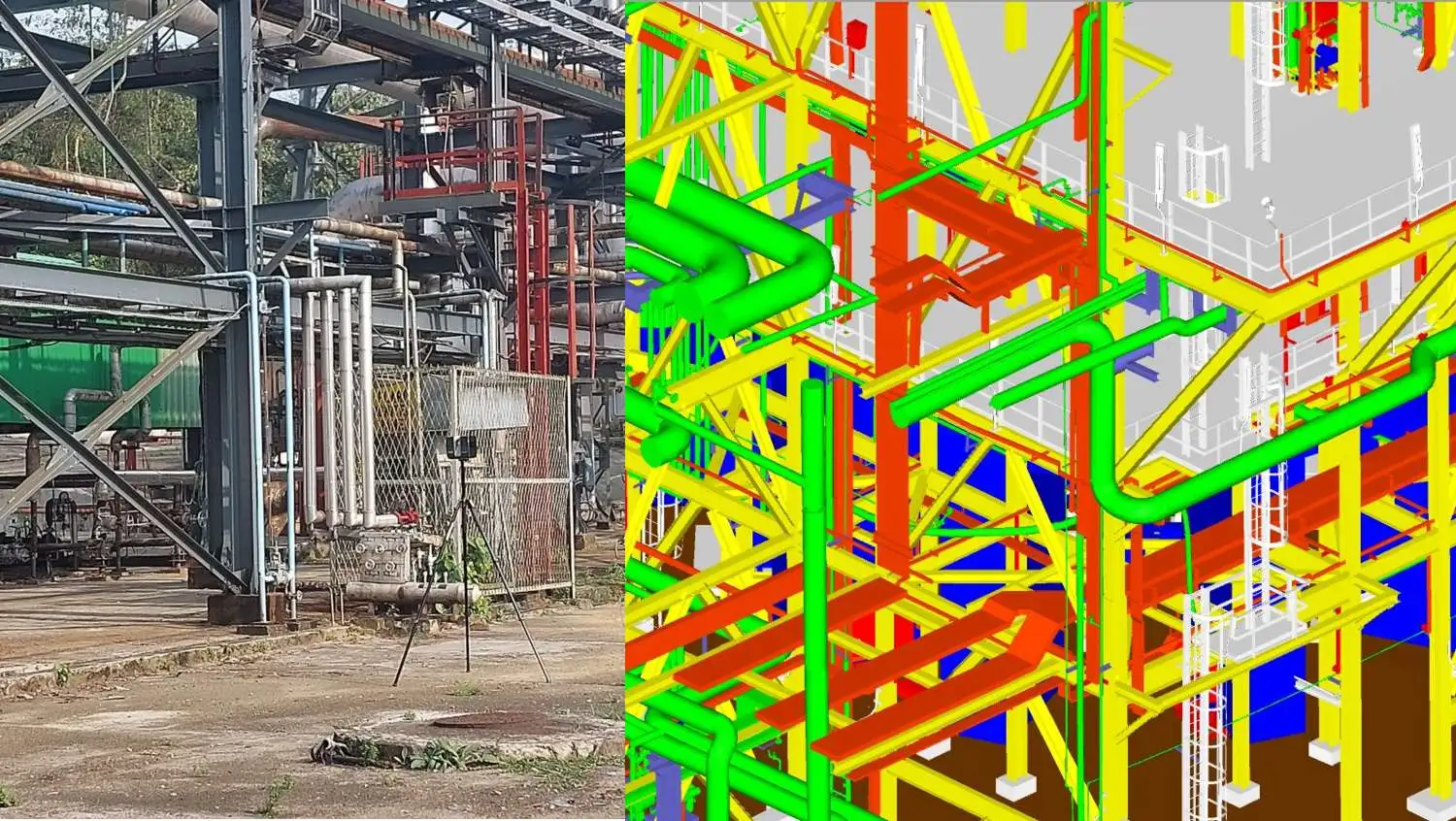

Our 3D plant scanning services also includes asset and facility management in multiple sectors such as mechanical, electrical and plumbing / piping design.The laser scanners like Faro create detailed and highly accurate 3D models with digitized documentation. These 3D models and documentations can be used for many things like.

Plant engineering services :

- Collision detection for retrofits, as-built documentation for CAD modeling, other plant design tasks.

- Plant rehabilitation

- Restoration, Digitization or revampment

- New equipment assembling, shifting or replacement Planning

- Plant Relocation & Estimation Studies

- Retrofitting

- Safety & rescue planning

- Construction sequence in new design

- Structural Stability Re-assessment analysis & RLA(Residual Life Assessment) Studies

- Deformation analysis

Meet With the Industrial 3d Scanning Services in Vadodara

In the industrial field, industrial 3D scanning services in Vadodara are a particularly helpful technology since they create complete records of an industrial facility by using 3D laser surveying to survey the structures that make it up. Improving plant management and making operations like equipment expansion, repair, or modification easier are the goals.

The owner won't have to worry about making mistakes or returning to the plant frequently to take measurements thanks to the 3D laser scanning of structures offered by industrial 3d scanning services in Vadodara.

Our skilled scanning & 3d Pipeline Scanning services in Vadodara team will work directly with you to fully understand your goals and position you for success. We employ the quickest and most precise 3D laser scanners available.

Our Scanning Technicians Visit You

3D laser scanning on-site is quick and simple. Following the completion of on-site data collection, we analyze the enormous volumes of data gathered to get it ready for CAD modelling. This procedure consists of:

- Aligning separate scans with one another

- Eliminating unnecessary or undesired information

- Conducting quality assessment and inspection

- Putting the information in the desired coordinate system

A specialised labour force for 3d Pipeline Scanning services in Vadodara and frequently multinational management corporations are required for industrial and factory building, which is a speciality form of construction.

Every area, whether it be a manufacturing plant, shipping centre, or warehouse, is planned and built to exact standards that fit the requirements of their construction procedures.

Construction documentation services from fibrox3d 3D can record the unique attention to every aspect of these properties, facilitate team communication, document the installation of specialised equipment, 3D plant Scanning in Vadodara and guarantee adherence to stringent safety construction rules.

Get Full-service Support From Fibrox3d

- Get wholesome support: Fibrox 3D plant Scanning in Vadodara provides industrial and manufacturing building with the documentation requirements it requires by:

- Delivery and Deployment of Equipment: Fibrox 3D webcam solutions provide for remote viewing possibilities for in-the-moment facility monitoring, and Fibrox 3D photo services may assist in making sure all equipment is delivered in perfect condition and installed appropriately.

- Safety Documentation: For years to come, Fibrox 3D video services may be used to record intricate machinery and system instruction. Make sure everyone is operating the equipment correctly, safely, and efficiently.

- Simple Access: To minimise knowledge loss in the case of personnel turnover, Fibrox 3D maintains all visual records and video on the cloud-based platform and app, which is available at any time.

- Quality Control: With a thorough as-built record attesting to your adherence to all industrial laws and regulations, you may avoid or dispute expensive legal action.

Utilising 3D laser scanning

- Using 3D laser scans by 3d Pipeline Scanning services in Vadodara, you may obtain an exact model for brownfield factories that already exist. You will be provided with the specific measurements, machine and tool locations, and lengths of pipework. Coloured models are another option that may be utilized widely as an immersive training tool for your employees.

- The Plant 3D Scanning in India that is produced can assist you in teaching your staff to provide better results and optimize working procedures and operational schedules. They are a great substance to utilise for the upkeep of plants.

- Before executing the PTW order, these models or scans are frequently utilised for vendor familiarization.

- By providing a dependable three-dimensional picture of the current factors to be planned against, laser scans can improve the precision and accuracy of augmentation planning. It makes it possible to develop prototypes that work with the current infrastructure.

An effective and advanced digital technology for manufacturing and building is Plant 3D Scanning in India. Its ability to scan both tiny and large items with ease and accuracy is a major factor in its industry success.

Because of its many advantages, laser scanning has caused a significant upheaval in the chemical sector. Firebox 3D is a recognised leader in laser scanning for management, as-build, and rebuilding applications in the chemical sector.

Our sophisticated equipment and engineers can do thorough scans of complex and elaborate facilities in a single on-site visit, saving time and avoiding the headaches that come with repeated inspections.