- A 3D printer

- Filament

- Slicing software

- Do you want flexibility?

- Can you handle the heat?

- Should it be too hard?

Introduction:

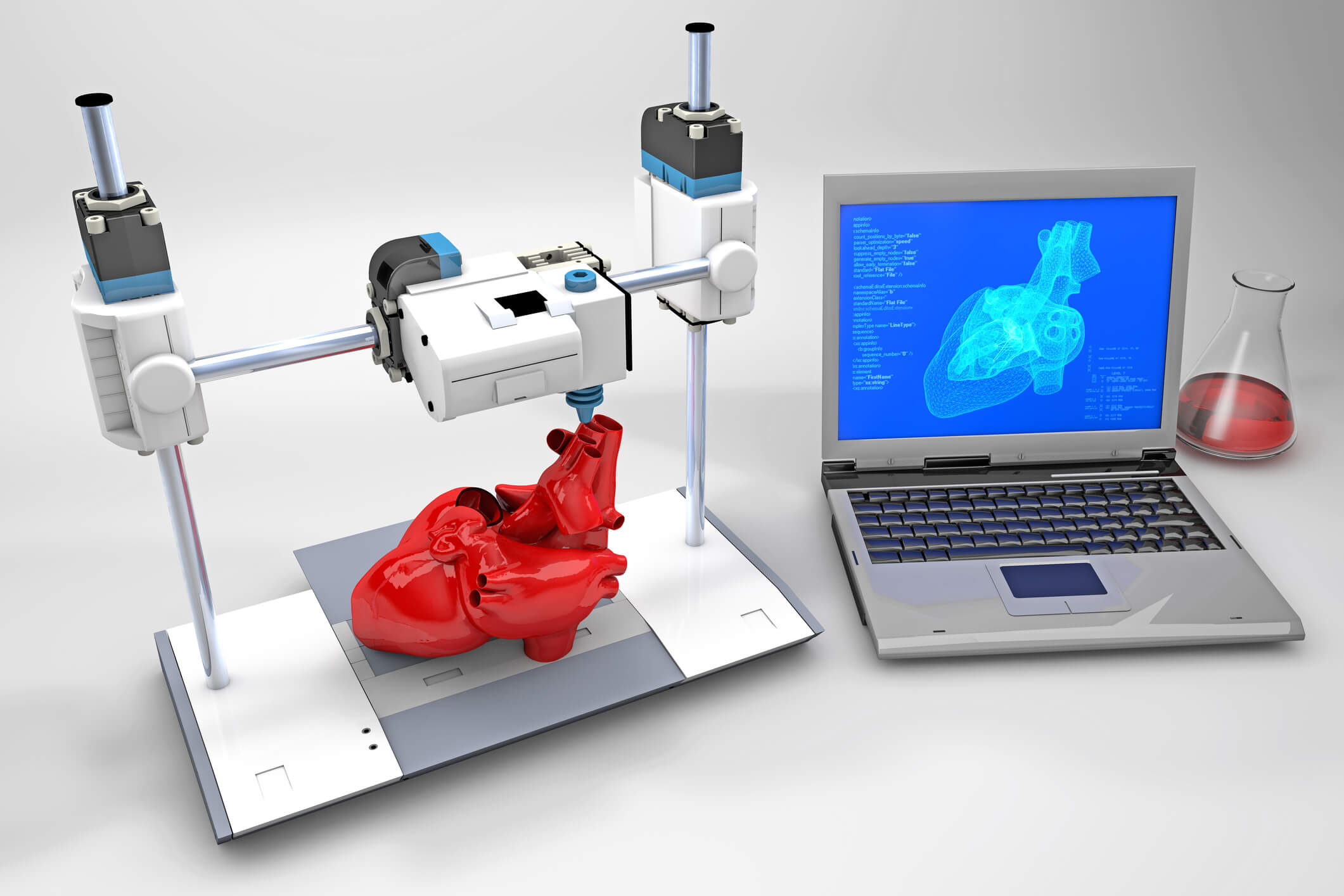

3D printing is a cumulative manufacturing process that creates realistic objects out of 3D models using thin filaments mostly made of plastic. Create a digital file from the sample that will eventually be sent to the printer. Although modern machines are expensive, there are cheaper models with quality printing and features.

Thinking about 3D printing and how to use it might be a little intimidating if you are new to 3D printing, Rajkot, because of the sheer amount of options and uses available.

3D Printing for Beginners: How to Get Started

Using specialized equipment known as 3D printers, 3D printing services is an advanced technology that produces tangible items from digital data.

There are usually three things you need to start with, but your exact demands will depend on what you want to print and what you want to publish.

If you plan to make your own art, you should also use the right art program. However, as mentioned above, you can also find many free tools online to download designs.

3D Printer Filaments

The choice of 3D printing service depends on a number of different factors:

Here are a few things to consider when choosing yarn.

Most beginners usually start with PLA. This is because PLA is relatively cheap and generally easy to print using standard techniques. Depending on your specialty, PLA can be a good starting point.

PET-G is more technical than PLA but is also considered a new co-material. However, it is good for sectors like technology and manufacturing. It is an ideal material for functional prototypes because it can withstand high temperatures and has a unique chemical structure suitable for these applications.

Software

There are two main services for 3D printing:CAD and slicing software.

Basically, you can use any CAD system that can produce a functional model. CAD is especially important if you want to create your own models and objects. Your CAD program should be able to export an STL file.

Another side of the slicing software equation. The software converts the STL file into a language understood by the printer. Gcode contains motion information that tells the printer how and where to move the axis, as well as how much material to load. Gcode is sent to the printer via SD card or Wi-Fi.

How to 3D Print:

Depending on the specific print you want, more or fewer steps can do your job. But in general, 3D printing also includes the following:

Create or Find a Design

The first step in 3d printing in Vadodara usually starts with a computer. If you can’t paint yourself, you can find many free tools online and free painting.

Export the STL file

When creating or selecting a design, export or download an STL file. An STL file stores information about the 3D object of your mind.

Choose Your Materials

You usually have an idea of what material you want to use before you start printing. You can choose different materials for 3D printing, depending on the function you want to use on your piece. We will discuss this in more detail below.

Choose Your Parameters

The next step is to define the different properties of your object and the printing process. Beginner’s guide to 3D printing includes deciding on print size and placement.

Create the Gcode

Then import the STL file into a sculpting program such as BCN3D Cura. The cutting software converts the data in the STL file into a special G-code with detailed instructions for the printer.

This is where the magic happens! The printer creates each layer of the object. Depending on the size of your object, printer, and materials, you can complete the process in minutes or hours.

Depending on how you want the final product to look or what material is used, additional steps such as painting, engraving, etc. may occur after printing.

Future of 3D Printing

According to a 2016 report, the 3D printing assistance market size was $5.165 billion in 2015 and is anticipated to surpass $30.19 billion by 2022. As more companies adopt the technology, 3D printing faces consumption.

Local production can significantly reduce supply costs and inventory requirements. Orders are printed on request.

Retail is increasingly turning to mass because of 3D printing, where every order can be customized down to the smallest detail and printed quickly. In every field it touches, 3D printing Rajkot is slowly changing our lives.

Conclusion

3D printing is now easier than ever. At first, many people thought 3D printing was something people couldn’t afford, but that sentiment has changed, and for good reason. It takes practice to perfect prints and designs, but learning 3D printing is a learned skill. Beginner’s Guide to 3D printing also offers a handy 3D printer, which is especially popular with schools and engineers.

Read More: Benefits of Using Laser Scanners for Construction Projects