- Reproduce a part without an original blueprint

- Change or upgrade a design for improved performance

- Do quality checks and failure analysis

- Build prototypes or get ready for mass production

- The latest 3D scanning tech

- Skills in CAD modeling and simulation

- Knowledge specific to your industry

- Solutions that are cheap and can grow with you

In today's quick-moving industrial scene, coming up with new ideas isn't just about making new stuff, it's also about learning from what's already out there and making it better. That's where reverse engineering services come in and change the game.

From cars to planes and factories to gadgets, industries in India are more and more looking to 3D scanning and reverse engineering services to boost their work, cut costs, and make better products. In this post, we'll look at the benefits of Reverse Engineering Services and why they are becoming a must-have for modern industries.

What is Reverse Engineering?

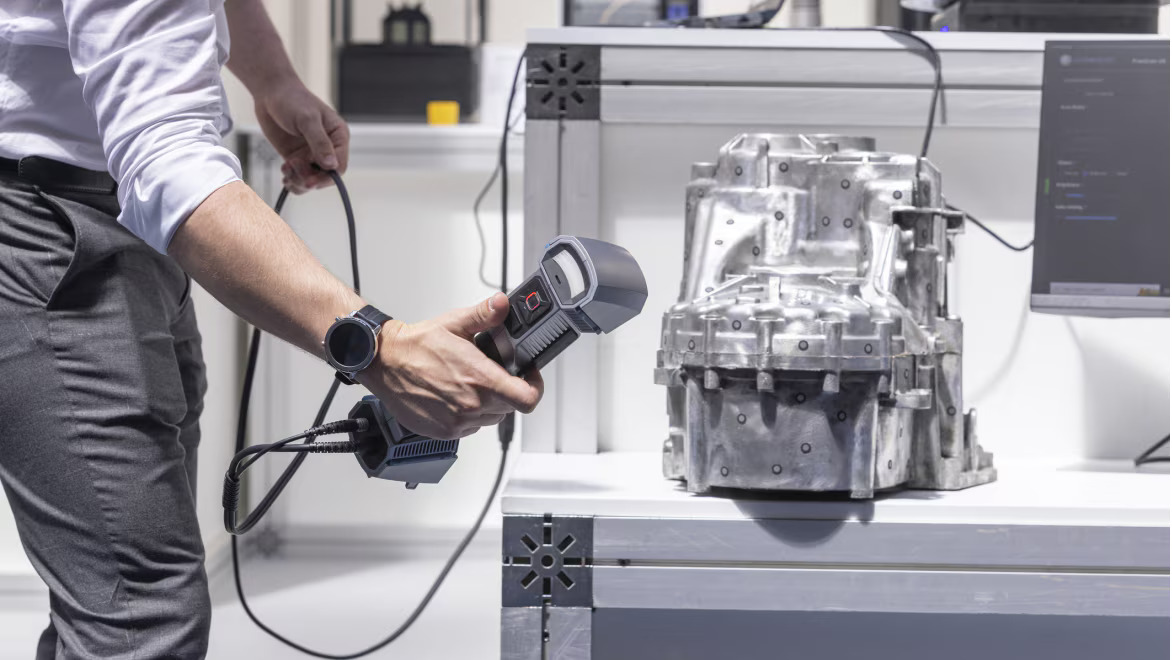

Reverse engineering has an impact on understanding a product or object's design, structure, and how it works. It aims to take apart the item, get useful information, and build it again or make it better. This process often uses high-tech tools like 3D scanners, CAD software, and tools to simulate.

In the past, people used 3D scanning and reverse engineering services in mechanical industries. It would be interesting to see how widely this applies, from medical devices to architecture and electronics, and even culture preservation in India.

How Do 3D Scanning Reverse Engineering Services Work?

It initiates by 3D scanning the current product or component. The scanning tech captures millions of data points to create a detailed digital model. After the 3D model is ready, engineers use CAD software to examine the design and recreate it or make it better as needed.

This information can then be used to:

Key Benefits of Reverse Engineering Services

Now, let's dig into some of the benefits of Reverse Engineering Services for today's industries in India.

1. Budget-Friendly Product Development

Creating a product from the ground up can take a lot of time and money. Companies can reduce their R&D expenses by examining an existing product through 3D scanning and reverse engineering services. This method proves useful for small and mid-sized Indian manufacturers who operate with limited funds and strict deadlines.

2. Substituting or Recreating Old Parts

The capacity to recreate outdated or phased-out parts stands out as one of the main benefits of Reverse Engineering Services. The company operated on a huge dataset and provided for this example enormous potential for improving customized healthcare in rural and semi-urban India, where it's negatively impacted by the lack of one. And look for the other characteristics to get and will benefit from reverse engineering services.

3. Boosting Innovation and Customization

Reverse engineering influences Indian manufacturers' ability to study rival products, spot flaws or strengths, and make better versions. This method sparks new ideas and lets companies create more tailored, productive, and market-ready offerings.

Take this example: A local car maker can take apart a part used by global rivals, make it better, and put it in their cars for less money, adding value for both the maker and the buyer.

4. Quality Control and Failure Analysis

Using 3d scanning reverse engineering services allows businesses to take a close look at products and spot defects or unusual features. This has a big impact on finding the root cause when products fail. In India, you have several sectors- maintaining railways, defense, and heavier machinery that continue to function on outdated systems.

Finding spare parts becomes a challenge, but 3D scanning makes the entire recreation process of these components more accurate and effective.

5. Speeding Up Time-to-Market

In a competitive market, being first often matters as much as being the best. Reverse engineering speeds up the product development cycle. It cuts down design time, makes testing easier, and speeds up manufacturing. The quicker a company can turn a concept into a product the better its chances to grab market share.

Indian startups in tech and hardware fields gain a lot from this. Rather than taking months to create a new design, they can use 3D scanning and reverse engineering services to roll out better products in weeks.

Applications of Reverse Engineering in Indian Industries

Here are some real-world cases of how different sectors in India are using the benefits of Reverse Engineering Services:

Automotive Industry

Car and bike makers in India reverse engineer imported parts to copy them, redesign components for better fuel economy, and develop aftermarket products. This cuts costs and backs the "Make in India" push.

Aerospace and Defense

As focus grows on local production, defense groups use 3D scanning to reverse engineer parts of foreign planes, missiles, and gear. This cuts reliance on imports and protects national security.

Manufacturing and Tooling

Firms in Pune, Ahmedabad, and Coimbatore often reverse engineer to enhance tooling and build die-cast 3D Printing molds for mass output. This boosts precision and cuts waste.

Healthcare and Medical Devices

3D scanning allows for the creation of custom prosthetics, dental implants, and surgical tools that fit better and feel more comfortable. Industries are going through the broken part, which is examined alongside the original 3D model, to see where any faults occurred, where the design or engineering went wrong, and possibly to enhance the process to avoid a repeat occurrence in the future.

Choosing the Right Reverse Engineering Partner

For various quality assurance measures, industries like aerospace, healthcare, and electronics are now in India, where reliability and safety are non-negotiable.

Companies in India that offer 3D scanning reverse engineering services are now working more with industries and putting more effort into research. This means businesses of all sizes can now use this technology.

Conclusion

The industrial scene in India is changing fast. To keep up, companies need tools to come up with new ideas, cut costs, and make better products all at once. The benefits of Reverse Engineering Services make them essential for modern Indian industries. Whether it's making an old part again, speeding up how products are made, or improving quality checks, 3D scanning reverse engineering services have an impact on how products are designed and sent out.

As India tries to become a global place for making things reverse engineering will no doubt play a big part in that goal. The future of industry isn't just about making new things, but learning from what's already been made and making it even better. Also Read About How Structured Blue Light Scanning Works: A Complete Guide