A traditional method for conducting slab flatness analysis is manual, labor-intensive, and time-consuming. Floor flatness/floor levelness (FF/FL), a commonly used method. It requires the creation of a grid on the concrete slab following a set of specifications before taking manual readings. ASTM E1155 standard method for determining floor flatness (FF) and floor levelness (FL) numbers typically take a measurement every foot along the grid lines. Using this manual method, even small projects often require an enormous amount of time to complete the data collection and analysis. Recently, however, contractors have begun to discover a new way to save a substantial amount of time and money on their projects is 3D laser scanning.

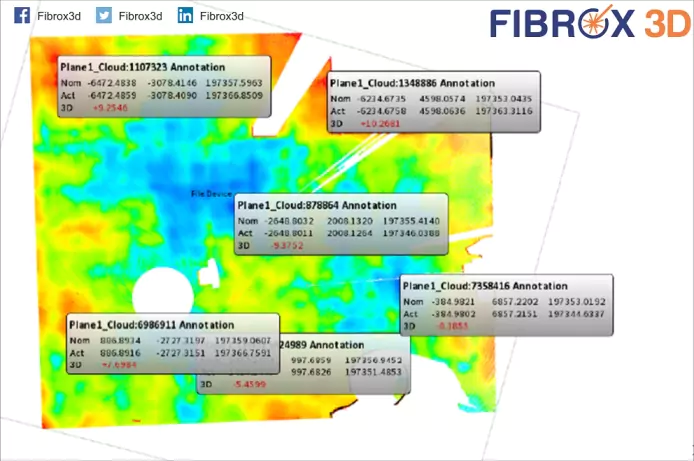

For all kinds of projects – from renovations to new construction –3D laser scanning collects rich, complete, and highly accurate as-built data to validate existing building documentation to ensure that new construction matches the as-design models, mitigating the risk of change orders. Laser scanning for floor flatness dramatically improves workflows and provides more effective deliverables.

Know more:

- 3D Laser Scanning in Topographical survey