Introduction:

3D printing is an innovation of the future and has changed production worldwide across industries. As one of the largest industrial cities in India and an emerging hub for technology, With a solid industrial base and educational and research set-up to boost the ecosystem of 3D printing manufacturing in Vadodara, making it an innovative hub for it.

In this blog, we cover the future of 3D printing in Vadodara and discuss how its presence can change industries that hold prominence as well as affect local education systems or entrepreneurship.

Current Landscape of 3D Printing in India

The Indian 3D printing market was worth over $79 million in 2021 and is anticipated to expand at a compound annual growth rate (CAGR) of nearly two decades. Few cities like Mumbai, Pune, and Bengaluru have already been a hotbed for 3D printing innovation.

In Gujarat, Vadodara is all set for the same. With the city being home to multiple engineering, petrochemical, and pharmaceutical industries using 3D printing services, Vadodara seems promising for these sectors.

In addition, with a constant emphasis on R&D (Vadodara has some good academic and technical universities as well), it is the right time for these institutions to step up in nurturing 3D printing talent and research.

Industrial Applications and Opportunities

Industrial applications are the prime factor driving the future of 3D printing in Vadodara. Key industries that the technology will serve include:

Manufacturing:

Vadodara's rich industrial base opens a huge opportunity for integrating 3D printing technologies with mainstream manufacturing.

Additive manufacturing means rapid solution of prototypes, economical small-batch production, and individual customization, which can lead to a shorter time before delivery and a less expensive product. That will foster innovation and allow local industry to be competitive on a global scale using 3D printing.

Engineering and Automotive:

The engineering landscape of Vadodara, especially automotive component manufacturing, can utilize 3D printing for precision parts, tooling, and assembly fixtures. Additive manufacturing allows 3D printing to speed up the dialysis product development process because an iterative design may be reviewed and individually printed.

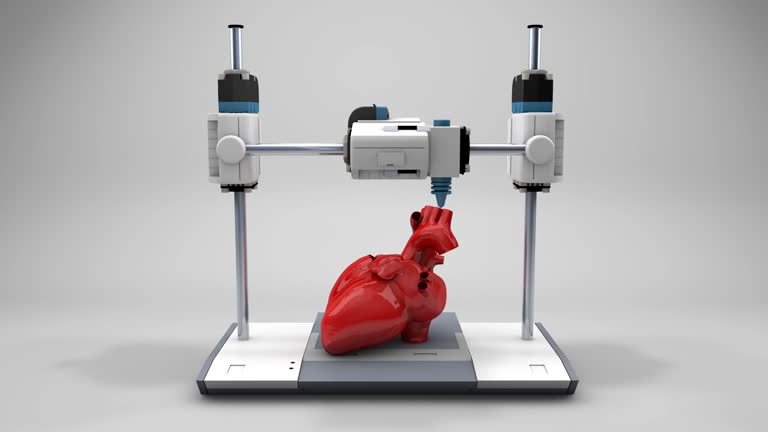

Healthcare:

The Vadodara medical and healthcare sector is a primary contender to gain immensely from 3D printing. Whether in prosthetics and implant production or medical modeling for surgical planning, the technology has redefined patient care. India being a price-sensitive market, this capability to manufacture custom medical hardware at almost 1/4th the cost is even more interesting.

Education and Research:

There is a growing trend of educational institutions in Vadodara integrating 3D printing as part of their courses, providing students with the competitive edge that this technology will require. Universities and research centers can utilize 3D printing for creative projects while expanding into the horizons of material science, robotics, and biotechnology.

Challenges and Roadblocks

Now, as for the future, 3D printing in Vadodara holds a promising view, but there are some challenges that need to be addressed:

Initial Costs: 3D printing services Vadodara can reduce end production costs, but using a printer and software on the front-end costs thousands of dollars per print run (10s to hundreds) for SMEs.

Lack of Awareness: Again, many businesses in Vadodara are unaware of the potential that 3D printing possesses, which will limit its mass acceptance. Focusing on educating the masses about it, training them, and also letting people know how useful this beast can be for them is what will help us grow in technology adoption.

Limitation of materials: Even though the 3D printing technology is advancing day by day, it still has some limitations when variations come into contact with different types of materials. It is also important to manufacture materials that are economically viable and conducive to mass production.

Skilled Workforce: However, the real success of 3D printing will depend enormously on having a workforce with deep knowledge in digital design software types, engineering, and material sciences. For Vadodara, he said the focus will have to be on creating a resource pool for professionals through specialized courses and training programs.

The Role of Entrepreneurship and Start-ups

Vadodara is increasingly becoming a hub of start-up activity, especially in technology-focused sectors. This is an opportunity for the upcoming ecosystem of start-ups in Vadodara to leverage resources, increase demand via more competitive alternatives (demand which can fuel growth further in India), deliver new medical devices faster and cheaper, and offer consumer products Western had become too expensive previously due to sunk capital towards scaling.

State support in the form of grants, tax allowances, and innovation hubs might go even further to stimulate start-ups into experimenting with 3D printing. Together, they can establish a thriving environment in Vadodara for 3D printing with the collaboration from innovative start-ups, established industries, and academic institutions.

Conclusion

The future of 3D printing in Vadodara is bright, with significant opportunities across multiple sectors. That said, addressing challenges, including cost-some software and suite awareness issues around 3D printers in schools, and a skilled workforce will be key to unlocking the value of Vadodara’s own brand of future-proofed manufacturing technology. When done properly with the right investment and planning, 3D printing services Vadodara can offer significant opportunity to stimulate economies while seeding tech future developments on a vast scale.

Read More: Top 5 Benefits of Using 3D Scanning Services for Accurate Data Capture