- India's largest reverse engineering team for any device or environment

- We provide production-ready models for reverse engineering of bikes, cars, or other sheet metal work in Rajkot city.

- Using our proprietary reverse engineering software, we quickly convert any 3D scan into an editable CAD model.

- Instant conversion of output from our reverse engineering service to any CAD system.

- Reverse analysis of cracked and broken parts and neutral parts in CAD files.

- Reverse-engineered interchangeable parts, custom ergonomics, and more.

- Consumer audio for making headphones.

- Dental and medical applications and how 3D scanning enables patient-specific workflows.

- Measurements to check and measure the accuracy of manufactured goods.

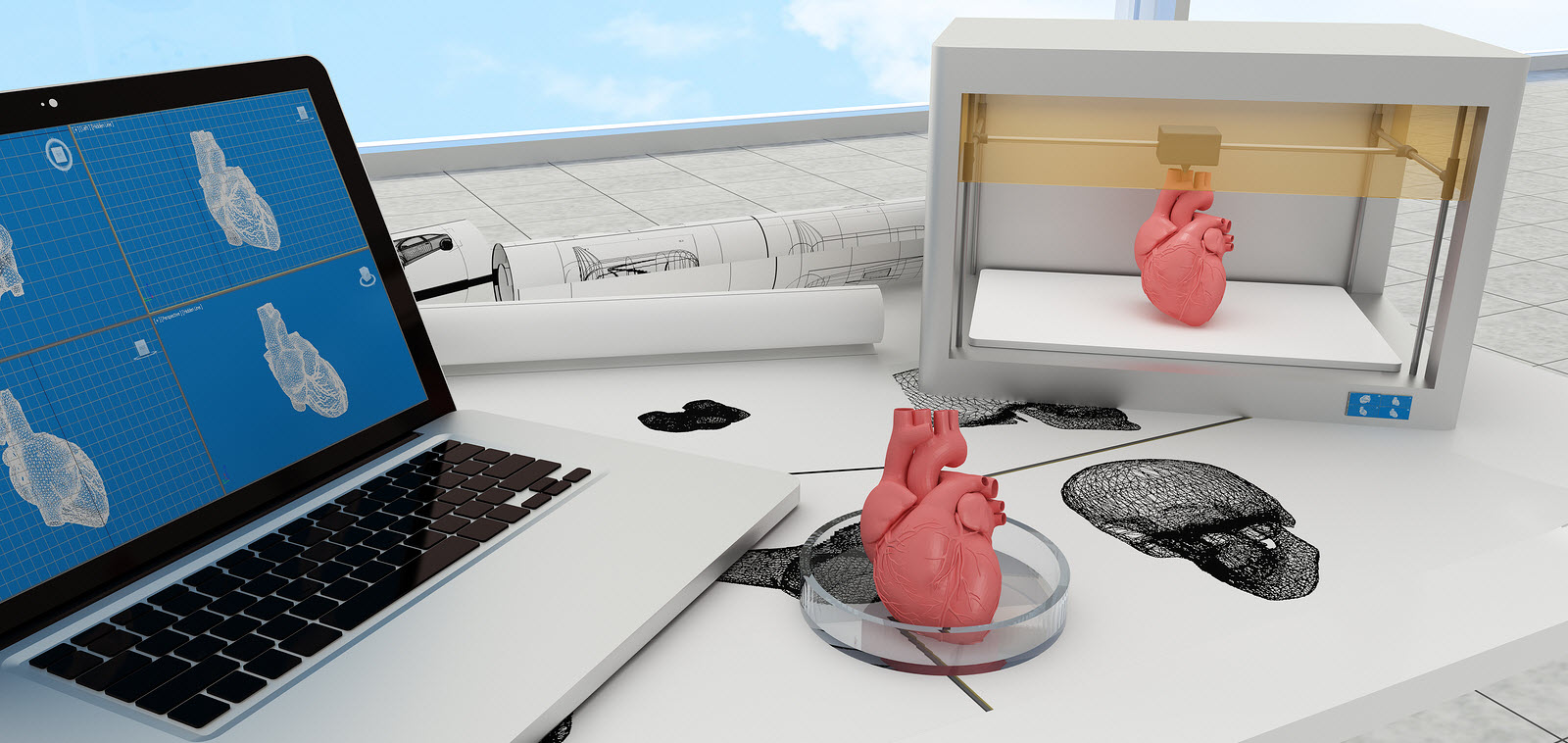

- 3D scanners and 3D printers are an integral part of the digital process in the industrial sector.

- Reasonably Priced

- Accessibility

- Waste Reduction

Introduction:

A 3D scanner for 3D printing in Rajkot plays an important role in the beginning and end of a 3D manufacturing process. While many factors affect the accuracy of 3D printing, a 3D measuring device provides a clear picture of material performance for complex applications.

Engineers, product designers, and scientists use 3D models to create digital models, whether using existing techniques through reverse engineering, uploading hand-carved brick models to a computer, or in person without knowing the exact physical shape of the body.

Professional 3D Scanners for 3D Printing in Rajkot

3D Printing Services by Descon Design

Founded in 2011 in Rajkot, Gujarat, Descon Design is a leading provider of digital printing services in India. Descon Design is one of the most established and trusted names for these services in India. With its extensive experience in digital printing services, Descon Design has popularized 3D scanner for 3D printing in Rajkot as satisfactory 3D printing services in the market.

Focusing on a customer-centric approach, Descon Design operates across India and serves a wide consumer base across the country. Get quality digital printing services from Descon Design in India.

Reverse Engineering Service in Rajkot

Inventive 3d

3D printing is a tool for unlimited creativity. It provides manufacturers and designers with a variety of product design options. 3D printing is taking industrial processes and research to a whole new level.

The manufacturing process is very simple and cost-effective, as the 3D printing process is part of the cycle. R&D teams can quickly test samples and make immediate changes, resulting in better, more accurate results.

How does 3D scanning complement 3D printing?

A 3D scanner extends the capabilities of a 3D printer to reproduce the design of almost any object. In some cases, scanning can be used to reproduce precise objects without the effort of CAD. A hybrid project that combines complex CAD models with digital 3D models can also be powerful.

Custom ergonomics, for example, physically follows a part of the human body and integrates it with technology. A 3D scanner for 3D printing in Rajkot is also an important tool for measuring product accuracy.

The combination of a 3D printer and a 3D scanner enables many powerful workflows:

What to Consider When Choosing a 3D Scanner for 3D Printing

When choosing a 3D scanner for 3D printing, it’s important to consider usability. Consider the features of the tool if you want to use it for rear engineering, rapid-fire prototyping, quality control, or anything else. Factors such as material size, forbearance, cost, and other conditions are important when choosing the right 3D scanner for 3D printing.

Other important considerations when choosing a 3D scanner for 3D printing include:

The 3D printing process is cost-effective compared to other manufacturing processes, such as powder coating. This is especially true for low to medium production volumes and more complex components.

However, 3D printers are generally more expensive than the cost of a comparable core. Despite the reuse of these raw materials, 3D printing is relatively inexpensive and therefore uses very few materials.

3D printing has become widespread over the past decade. This goes back to some key patents that expired in 2009. It enables a large and accessible online collection of 3D printing best practices, troubleshooting, and general optimization techniques for a growing user base.

Consider frequently scanning items. Choose a 3D scanner that offers the range, scan area, and resolution to scan parts. Choosing a 3D scanner with different possible configurations increases its versatility.

A 3D scanner for 3D printing in Rajkot helps to reduce minimal waste. These fragments often become part of the supporting structures that are removed after printing on SLS-printed parts. These support structures are best designed to be as light as possible. Waste reduction methods involve the disposal of large amounts of waste.

Other technologies, such as 3D printing, are designed to selectively add materials as needed. This compensates for the small amount of wear caused by the supporting structures.

Conclusion

A 3D scanner for 3D printing in Rajkot is useful in manufacturing and engineering, mainly because it solves many old problems, from the simulation of existing components to the creation of prototypes. With just a ready digital 3D printer for your part, you can 3D print just about anything.