- Laser scanners: Use lasers to emit to measure the distance of the surface.

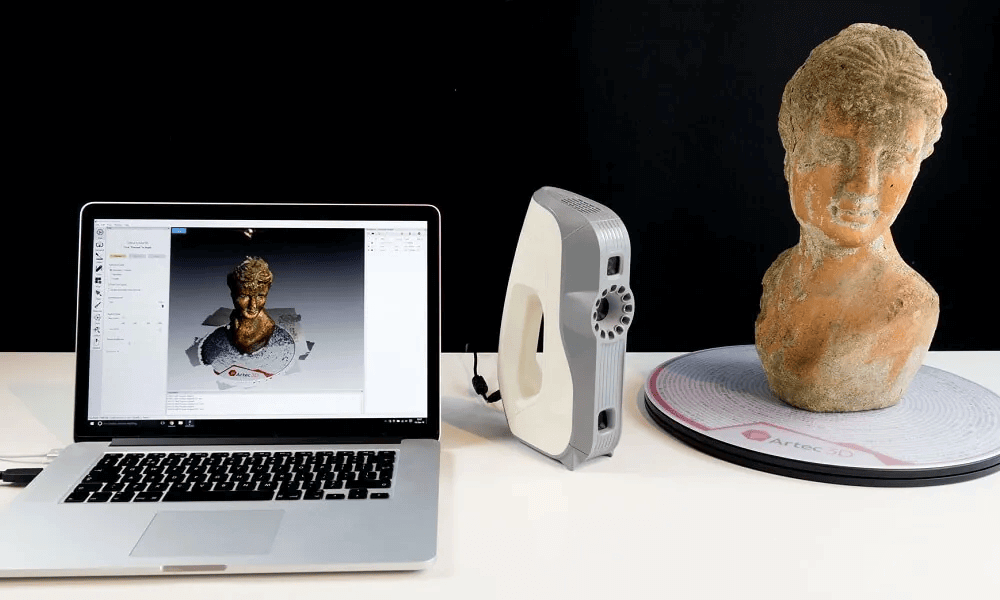

- Structured Light Scanners: They project patterns of light onto an object and analyze distortion to figure out shape.

- Photogrammetry: Uses many 2D images to build a 3D model.

- Contact-Based Scanners: Using probes to touch and obtain a measurement of an object.

- Calibration issue of the scanning device.

- Variability of lighting conditions.

- Movement or shaking while being scanned.

- Misalignment of several scans.

- Software limitations in the reconstruction of the last 3D model.

- Resolution and Precision: The high-resolution scanners can capture smaller details.

- Scanning Range: Some scanners perform well only at close range (e.g., handheld scanners), while others can be used at long distances (e.g., LiDAR scanners).

- Portability and Ease of Use: Handheld scanners provide mobility but may need additional stabilization for precision.

- Using Manufacturer-Recommended Calibration Tools: Many scanners come with calibration targets or even software to assist calibration.

- Routine Calibration: Long Before Scanning: Confirm your calibrators before major scanning sessions.

- Verifying Scanner Alignment: This is a random pattern with the outcome of verifying if your laser beams/cameras/sensors are laser correct.

- Never put it in direct sunlight or in ambivalent light conditions, which can exercise a wedge and distortions.

- For structured light scanners, ambient lighting must be uniform.

- Glossy or reflective surfaces are harder to scan than matte ones.

- Spray shiny stuff with a scanning spray to minimize reflections.

- Extreme temperatures affect the performance of the scanner.

- Condensation can form on lenses or scanning equipment in high humidity.

- Keep the scanner at the best possible height and distance from the object.

- Scan the range recommended by the manufacturer.

- For multiple scans, make sure there's enough overlap (i.e., pre-scanning 30-50%) between scans to assist with alignment.

- Software relies on overlapping scans to stitch images together accurately.

- Scan from a variety of angles to ensure complete capture of the object.

- Be vigilant with complex geometries and hidden features.

- Scroll without sudden movement when using handheld scanners.

- To prevent gaps in data, use a systematic scanning path.

- 3D laser scanning services in India remove noise, outliers, and redundant data points.

- Use software tools to filter unwanted artifacts.

- Fill small gaps in the scan data while preserving fine features.

- Use algorithms to interpolate missing data without distorting accuracy.

- Keep the file size within acceptable limits while still maintaining adequate detail.

- Simplify polygons without losing accuracy.

- Noise Reduction: AI can detect and remove scan artifacts.

- Feature Recognition: Using machine learning, it is able to align multiple scans accurately.

- Smart Mesh Refinement: Automatically fill holes and improve surface details without the need for manual work.

- Rushing through the Scan Process: Getting too fast causes data loss and misalignment.

- Not Accounting For Scanner Warm-Up Time: Some scanners require a few minutes to warm up before optimal performance is achieved.

- Scanning in Non-Ideal Situations: Vibrations or motion can compromise the integrity of the scan.

- Neglecting Regular Equipment Maintenance: Dust buildup and misalignment can result in performance degradation.

- AI Based Corrective Scans in Real Time: Artificial Intelligence will enhance the exactness of scans throughout the data acquisition process.

- Edge Computing in Scanning Devices: On-device processing will make data handling quicker and reduce error.

- Enhanced Mobile 3D Scanning: Smartphones will enable accurate LiDAR-based scanning.

- Quantum-Enhanced 3D Imaging: Future quantum sensors could significantly increase resolution and precision.

Introduction:

3D scanning has transformed various industries, including manufacturing, healthcare, architecture, and cultural preservation, allowing for the accurate digital duplication of tangible items.

But there are lots of things that one should keep in mind if you want good accuracy in 3d laser scanning services india, including scanning techniques, environmental conditions, equipment. calibration, and data processing.

In this blog, we delve into the best strategies for 3D scanning optimization for accuracy, including hardware. selection, scanning best practices, post-processing techniques, and environmental factors.

Understanding 3D Scanning and Its Challenges

How 3D Scanning Works

3D scanning refers to the ultimate process of capturing objects in 3D, including their shape, texture, and dimensions, and converting it to a digital model. Some of the more common types of 3D scanning technologies are:

Challenges in Achieving High Accuracy

Best Practices for Optimizing 3D Scanning Accuracy

1) Choosing the Appropriate 3D Scanner

2) Proper Scanner Calibration

One active ingredient is regular calibration for scanning accuracy. Best practices include:

3) Optimizing Environmental Conditions

Accurate 3D data capture is largely based on the scanning environment. Key factors to consider:

Lighting:

Surface Preparation:

Temperature and Humidity:

4) Mastering Scanning Techniques

Scanning with the correct technique can have a major impact on accuracy:

Consistent Scanning Distance:

Proper Scan Overlap:

Using Multiple Angles:

Moving Slowly and Steadily:

5) Optimizing Post-Processing for Accuracy

Once scanned, post-processing the 3D model corrects inaccuracies. Key techniques include:

Point Cloud Cleaning:

Hole Filling and Surface Smoothing:

Optimizing Mesh Resolution:

6) Leveraging AI and Machine Learning for Enhanced Accuracy

With them, the accuracy of the scanning process will become better by means of:

Common Mistakes to Avoid in 3D Scanning

Even the best tools can fail at times, affecting the accuracy:

Future Trends in 3D Scanning Accuracy Optimization

Here are some trends in the evolving technology that will enhance 3D scanning accuracy:

Conclusion

Accurate 3D data capture is dependent on several factors, including hardware choice, scanning methods, environmental conditions, and post-scan processing. With regular calibration and high-quality software and AI integration, even bionic limbs can be extremely accurate. When you adhere to these movie standards within the industry, you’ll find yourself with accurate and trustworthy 3D scans, which yield higher design processes, improved manufacturing quality, better medical imaging, and reliable historical preservation. Also Read About LiDAR Mapping for Construction

6